|

Westinghouse Prototype Rectifier (Developmental UX-280) |

|

| This tube is

a developmental full-wave rectifier made by Westinghouse, most likely

late in 1926 or very early in 1927. It represents an important

step in the process which began with the

UX-213 that was designed and

produced by General Electric, and eventually

led to the production UX-280 tube and a long series of variants,

including, most notably, the 5Y3, the 5U4, and many others. The only markings on this tube are a paper sticker and the standard RCA logo and licensing notice on the base. There are no engraved type numbers on the base, as was normally done at the time. In some ways, it resembles the UX-213, particularly the box-like rectangular plate structure, though the filament is much different than the thoriated tungsten used in the earlier tube. One of the goals of the tube designer in those early days was to provide a more efficient electron emitter that also required less power in operation. One solution was to coat the filament with compounds such as barium or strontium oxides which were particularly good at emitting electrons when heated. This technique was well known by the mid-twenties, and seen most notably in tubes like the Westinghouse WD-11 and WD-12, and many Western Electric types such as the 102, 203, 205, 215, and 216 families. The filaments in these early tubes were typically either pure platinum, or an alloy of platinum and iridium in a ratio of 90% to 10%. Then, as now, these metals were expensive, so that reason alone justified a search for an alternative. At the time, platinum cost $180 per ounce. Dr. Erwin Foster Lowry, a research scientist for the Westinghouse Research Laboratories, sought just such a replacement, and he arrived at an alloy consisting of nickel, cobalt, iron, and titanium (approximately 73%, 18%, 7%, and 2%). He called this alloy “Konel”. While developing this alloy, he discovered that the electron emissivity of the oxide coating was influenced by a chemical interaction between the oxide and the metallic base. In other words, the base metal provided more that just the heat and mechanical support. The Konel-based filaments showed significantly higher emission levels than platinum filaments for the same input power. In addition, Konel had strength and ductility characteristics that made it ideal for the purpose. In fact, Konel became stronger at high temperatures, rather than the reverse. Lowry applied for a patent on this alloy on October 28, 1926. The patent, number 2,140,367, titled “Thermionic Cathode” was finally issued on December 13, 1938. Konel was officially announced to the world on September, 9, 1929. Pubic notice appeared via brief articles such as this in various newspapers. This material was described by Lowry in a paper published in Physical Review (the publication of the American Physical Society) early in 1930. This Westinghouse advertisement appeared in Popular Science magazine in the October, 1930 issue. The tube shown here has filaments consisting of oxide-coated Konel ribbons, as was clearly documented on the paper stickers. |

|

|

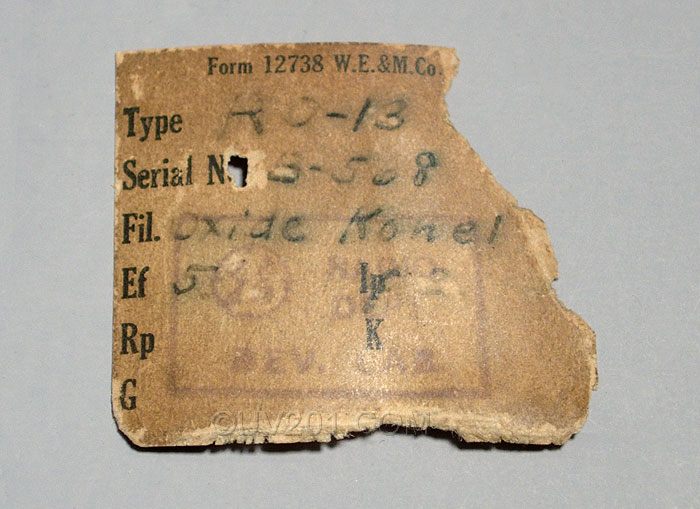

Two stickers were found on this tube, one was directly on top of the other. Both of these stickers were marked "W. E. & M. Co. Eng. Dept." This stands for "Westinghouse Electric and Manufacturing Company Engineering Department". Shown above is the top level sticker. The type number, serial number, filament type, and voltage are all clearly marked. What is most interesting is the faint ink stamp. The GE logo is present, and the words "Radio Dept. Dev. Lab." So, what this means is that this tube originated with Westinghouse, but somehow it found its way to a GE group that was designing radios. The RCA Radiola 17 (released in September, 1927) was a GE design, and it was also the first RCA radio to use the UX-280 rectifier tube. My belief is that RCA provided tubes like this to GE to use in that development project prior to May 1927, when the production UX-280 became available. |

|

|

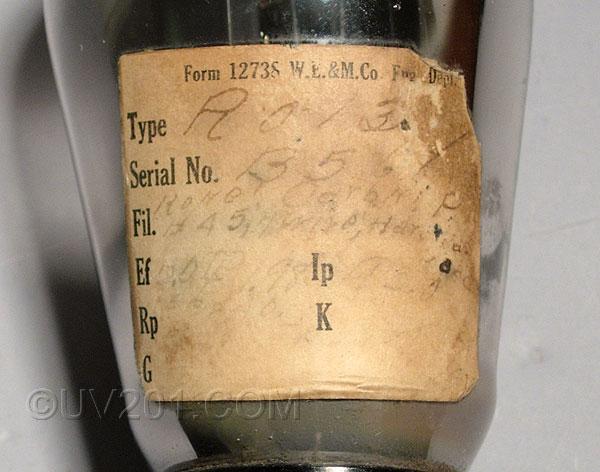

The upper level sticker was mostly loose when I got the tube, so I removed it, revealing the lower level sticker. The information recorded on this sticker is at a more technical level than what is on the upper sticker. The type number and serial number are as seen on the upper sticker. Below that is the line "Konel, Carb Ni P". This shows the filament material and the plate material, which was nickel coated with carbon (for improved heat dissipation). The remaining markings are hard to read and interpret, but there is some information about the filament wire, and then filament voltage, filament current, plate voltage, and plate current. So, apparently this tube began it's life as a laboratory test vehicle and the designers were well enough satisfied with its performance to release it to the application developers. When the tube was transferred to GE, the second sticker was added to cover the first, and it provided just enough information to identify the tube. GE then added their own marking to the sticker. The tube is still functional, though it's weak, mostly because much of the oxide coating has flaked off of the filaments, a common end-of-life problem with tubes of this sort. |