|

RCA UV-200 and UV-201 Series Tubes |

||

|

Just after WW-I, it was impossible to legally manufacture a useful vacuum tube for sale to the public because the essential technology was tied up by a series of lawsuits over two interlocking patents controlled by competing companies. The Fleming Valve patent was owned by the American Marconi Co. and the DeForest grid patent was licensed to Western Electric . A temporary agreement allowed Moorhead to make legal tubes on a limited basis, but a long term solution was needed. The formation of the Radio Corporation of America (RCA) was the arrangement by which this conflict was resolved, and the serious production of vacuum tubes could proceed. The introduction of the UV-200 (detector) and UV-201 (amplifier) tubes by RCA late in 1920 literally allowed the radio boom of the 1920's to begin. The tubes shown on this page represent a sampling of the many variants of the tubes that were sold under the RCA name and made by General Electric and Westinghouse during the 1920's. |

||

This picture appears here courtesy of Kenneth Scharf, WA2MZE |

The tube shown

to the left is one of the earliest examples of the UV-201. It was made

by GE in or about December, 1920.

The earliest tubes used the Shaw base (made by the Shaw Insulation Company) which was machined from a length of brass tubing. The insulating insert holding the pins was molded in place, and generally (though not always) bore the Shaw logo at the center of the pin circle. The later bases were stamped from a thinner brass sheet stock, and used a ceramic insulating insert. (The picture below is of a Shaw base on another tube.)

|

|

|

|

|

| The

two tubes shown above are slightly later examples of the UV-200

(left, GE) and the UV-201 (Westinghouse). They use the later type

sheet metal brass base.

These tubes were made anywhere between December 1920 and September 1922. All of the early tubes show the original RCA logo (the letters R and C inside a circle) etched in the glass. The plate structures of the earliest tubes are distinctive. In these tubes, the four tabs which support the plate were formed by cutting diagonally into the plate and bending them out where they were welded to the support wires. A number of examples of UV-201's made both by GE and Westinghouse show a distinct gold coloration. Several explanations for this coloration have been proposed. Some claim that tinted glass was used. Others suggest that tungsten was gradually vaporized from the filament during use and was deposited on the inside of the bulb, thus causing the coloration. I believe the latter explanation is the case, but I would have to break a tube to be sure. That I am not about to do. Westinghouse also made another, completely different tube that also bore the UV-201 type number. It may be seen here. |

||

|

|

|

| These two tubes are UV-200's made by GE. RCA adopted the familiar "meatball" style logo in August, 1922. They were briefly made with the logo etched in the glass, but they switched over to the cheaper paper label at some later time. These labels are often missing. | ||

|

|

|

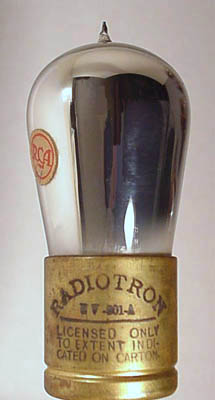

| In October 1922, the UV-201-A replaced the UV-201. The "A" version used a thoriated tungsten filament, which required less power than the pure tungsten filaments of the UV-200 and UV-201. For some reason, the corresponding filament change did not take place in the UV-200, so the UV-200 continued in production until sometime in 1924. The curved "Radiotron" marking on the base of the tube on the right is a later version, and was maintained after the switchover to Bakelite bases. | ||

|

|

|

| An interesting

variation that is unique to the General Electric UV-201-A tubes involved

the chemical process by which any residual oxygen inside the tube was

eliminated after the bulb was sealed (known as the "getter").

Most tubes used a magnesium getter, which produced the familiar silver

appearance inside the tube. GE, at their Nela Park plant near

Cleveland, Ohio, used an

alternate phosphorous-based compound, which produced the rainbow effect

seen on the two tubes shown above. The function of the tube was

the same, but these "rainbow" UV-201-A's are quite rare and

sought after.

Note also the tube on the left is a Cunningham variant (a C-301-A), as can be seen from the "C" logo on the paper sticker.

|

||

|

|

|

| Starting about March

of 1924, the characteristic tip at the top of the tube (where the tube was sealed during

manufacture) was phased out. The tipless brass-based tubes (UV-200

and UV-201-A) remained in production until about April 1925, when the Bakelite based tubes were introduced. The paper sticker has

also been abandoned at this point, replaced by the

etched RCA logo at the top of the tube.

|

||

|

|

|

| The brass base was abandoned in April 1925 in favor of the much cheaper molded Bakelite bases as shown here. The short-pin UV base, as seen on the UV-201-A in the left picture, lasted until August 1925, when the long-pin UX base replaced it, as on the UX-201-A tube in the right picture. The UV-200 was also made briefly with a Bakelite base. | ||

|

||

|

This unusual UV-201A tube was made by Westinghouse. Apparently, Westinghouse stayed with the tipped design longer than GE, so a very few tipped tubes with Bakelite bases exist. It would appear that all (?) of the brass-based UV-201A tubes without tips were made by GE. The base markings on this tube are stamped on, rather than engraved. Identical tubes without the tip are more frequently seen, though not exactly plentiful. |

||

|

||

|

Another unusual variation of the UX-201A is this one with the RCA "Meatball" logo stamped into the plate. It is similar to the UX-112 shown elsewhere on this site. It has been theorized that these tubes with the RCA logo were specially made as promotional items for trade shows or dealer displays. Since most UV-201A and UX-201A tubes had a very heavy getter flash (the silvery coating in the tube that was meant to absorb any oxygen which would shorten the life of the tube), the logo on the plate would not be visible. So, it appears that, for this run of tubes, they didn't use the normal getter. The tube was subjected to a more thorough evacuation process so it didn't need the getter, but made it a more expensive tube. But, for a promotional item, that wouldn't have mattered. I understand there was also a UX-200A with the logo plate. This photo appears courtesy of fellow collector, Robert Lozier. Visit his website here. |

||

|

|

|

| The UX-200 replaced the UV-200 in August 1925 and remained in production until May, 1926 when it was replaced by the much improved UX-200-A. The UX-200-A and the UX-201-A remained in production into the early 1930's when the UX-200-A was discontinued, and the UX-201A was replaced by the ST-bulb 01A. | ||

|

|

|

|

|

|

| Shown above are the four important base variations used on these tubes. The top left is the brass UV base, with the ceramic insulating insert, and short pins (1921-1924). The top right is the Bakelite short pin UV base (1924-1925). The bottom left is the long pin UX base with brass pins (1925-1927), and the bottom right is the UX base with nickel plated pins (1927 and later). | ||

|

Cunningham released one of the first tube manuals in 1926. It was not in the book format that most collectors are familiar with. Rather, it was in loose leaf format in a soft cover binder. I have scanned the pages of this manual that covered the CX-301A tube (equivalent to the RCA UX-201A), and a section that described the process by which these tubes could be brought back to life after being abused in operation. The CX-301A article (in .pdf format) is here. The reactivation article (in .pdf format) is here. |

||